At Barli, we create healthy products for a healthier world

Production of agricultural products using rapid freezing (IQF) technology

Fruits

Frozen Sour Cherries

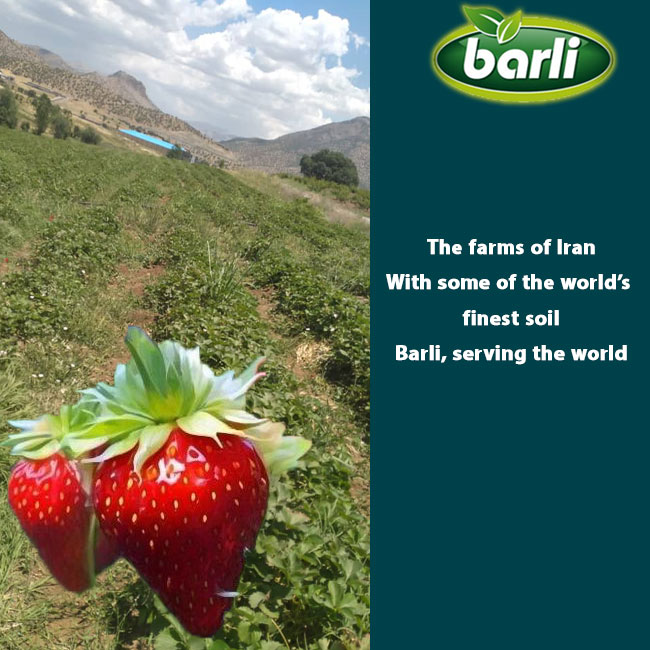

Frozen Strawberries

Frozen Black Raspberries

Frozen Pitted Cherries

Vegetables

Frozen Broccoli

Frozen Sweet Corn

Diced & Sliced Carrots

Cauliflower Frozen

The Best Healthy Nutrition in Your Hands

Delicious Recipes with Barli Products

Mexican Corn

Instructions

about barli

State-of-the-Art IQF Technology:

All products at Barli are processed using IQF rapid-freezing technology with the best modern machinery available worldwide.

Premium Agricultural Ingredients:

Barli sources only the highest-quality raw agricultural materials, carefully inspected by our quality control team and agricultural engineers to ensure top-notch products.

High Production Capacity:

Barli’s large production capacity enables extensive cultivation of agricultural lands, boosting the agricultural processing industry.

Planned & Monitored Production:

Raw materials are selected and monitored by expert engineers according to planting and harvesting seasons to ensure top quality.

Founded with Advanced IQF Technology:

Barli started in 2006 producing frozen agricultural products using state-of-the-art IQF technology, becoming the first factory of its kind in Mazandaran by 2009.

Modern Facilities:

The 6,000 m² complex includes equipped cold storage to support export production and distribution, ensuring freshness and quality in every product.

Learn more about the various nutrients found in fruits, vegetables, and healthy foods

Barli Healthy Products Magazine

Company Sustainability Report

For over 50 years, we have taken pride not only in delivering nutritious, high-quality products worldwide, but also in our responsibility toward the land where our products are grown. We are equally committed to supporting and empowering the global communities that make it possible for us to produce and supply these premium products.

Our sustainable commitment extends to the responsible cultivation, processing, and distribution of our products—today and for generations to come.

IQF Rapid Freezing Method

This method preserves the original properties of the product, such as flavor, color, and aroma, and prevents the formation of ice crystals in the product’s structure, ensuring freshness. Products can be stored at -18°C for up to 2 years.

In this process, raw materials are first washed, disinfected, and enzymatically treated using fully automated systems without hand contact. They are then directed to a specialized freezing tunnel, where they are frozen individually in a flow of -35°C cold air. This separation prevents microbial growth, resulting in a highly durable product ready for distribution.

Benefits of Rapid Freezing

Year-Round Availability: Easy and continuous access to products throughout the year.

Reliable Supply for Food Industry: Food manufacturers, restaurants, hotels, catering services, and more can access high-quality raw materials.

Reduced Waste & Transportation Costs: Minimizes agricultural losses and lowers shipping expenses.

Nutrient Preservation & Hygiene: Maintains nutritional value over time while ensuring completely hygienic production.

Export Potential: High product durability enables efficient export of frozen goods.

Environmental & Health Benefits: Prevents environmental contamination, protects family health, and optimizes the use of factory by-products.

Quality Assurance:

The complex features a fully equipped laboratory to monitor both incoming raw materials and finished products. All processes are supervised by food science experts, ensuring the highest product quality at every stage.